Fire Fighting

Fire Fighting

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

Fire Fighting

Fire fighting systems and equipment vary depending on the age, size, use and type of building construction. A building may contain some or all of the following features:

>> Fire extinguishers

>> Fire hose reels

>> Fire hydrant systems

>> Automatic sprinkler systems

Electrical & Mechanical Work

Electrical & Mechanical Work

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

Mechanical Work

Our complete approach that distinguishes us in all our projects especially benefits us in the turnkey area. Particularly, in the business field of turnkey plant engineering and construction.

We can optimally play the card of the extensive range of business activities in the company: integrated engineering, and installation and erection competencies from a single source, controlled through central project management.

We consider an early involvement with the installation and erection teams in the engineering process to be an essential requirement in order to establish efficient construction processes, avoid re-engineering and be able to realise a maintenance friendly industrial plant.

Electrical Work

Building systems and their respective subsystems, equipment, and components are an intricate part of the function and operational goals of a building. Industrial Electric maintains a high regard of the importance for producing the most quality efficient building systems using top of the line componentry and precise installation. We stay current with the newest technologies and strategies to meet and exceed any customer’s job demands. We utilize state of the art fabrication facilities, in house CAD and engineering services, and proven third party involvement to ensure consistent quality, safe equipment, and fast and reliable service.

Industrial Electric building systems include:

- Switchboard, transformer and panel board distribution

- Switchboard, transformer and panel board distribution

- Lighting and control

- Lighting and control

- Mechanical equipment connections and automation

- Convenience device and receptacle power

- Mechanical equipment connections and automation

- Lightning protection and grounding

Pre-Engineering Building

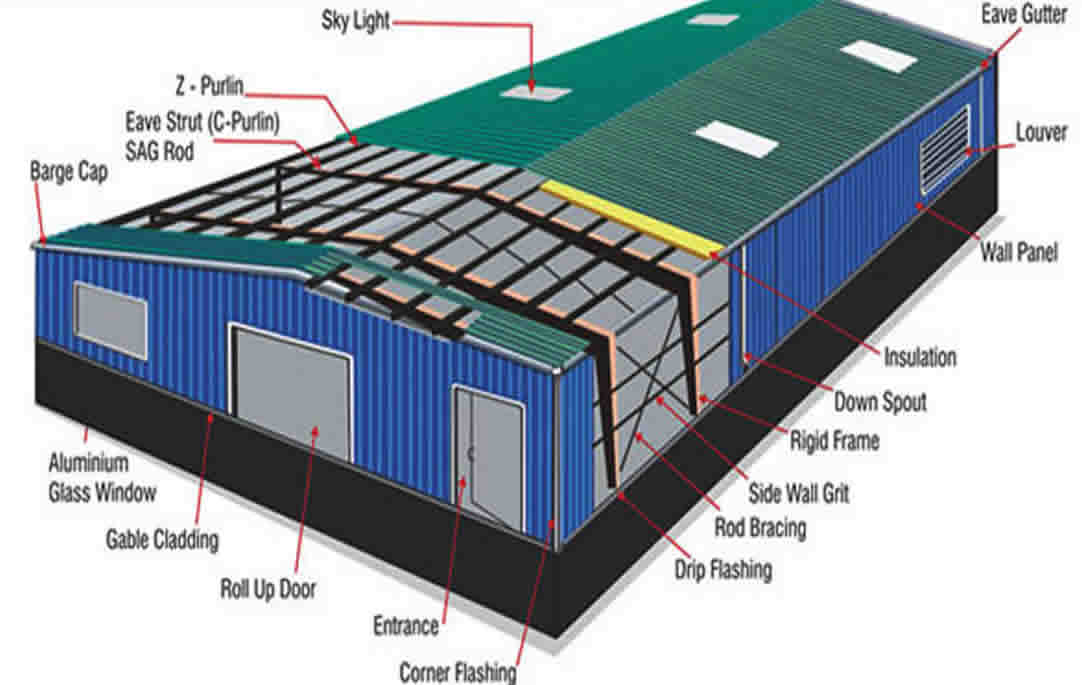

PRE ENGINEERING BUILDING

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

BUILD FAST AND BUILD SMART

PEB

The Pre-engineered Buildings Structures are custom designed, precision engineered with minute detailing so as to ensure the efficiency of the final structure. These are lightweight with good and (of) high strength, making it easy to erect and will meet any weather condition. The PEB´s are flexible, durable and adaptable. ABR Pre Engineered Buildings comes with a highly efficient external and internal drainage system.

ABR Metal Roof Structures can be built in minimum time and thus makes it an ideal choice for making all non-residential, wide-span and low-rise buildings for long life.

We, ABR provide these Steel Roof Structures (PEB´s) with a variety of structural and non-structural additions based on the customer´s specific requirements and design. We provide turbo vents, trusses, fascias, color coated roof sheets, daylight sheets, etc.

Advantages of using our PEB Structures

- Economic & Cost Effective

- Factory Controlled Quality

- Durable

- Longevity

- Flexibility in expanding

- Environmentally friendly

- Faster Installation

FEATURES THAT MAKES

PEB INVALUABLE

- Competitively priced

- Quality and innovation assurance

- Provision for easy future expansion

- Fastest delivery time & speedy erection

- Transported in a knockdown condition

- Low maintenance cost

- No welding facility required at the site

- Re-locatable and re-workable

- Attractive modern appearance

- Insulated to suit various weather conditions

- Ability to withstand seismic forces

Pre Engineered Buildings are custom made to suit a wide range of application in different industry sectors. It largely depends upon the requirement of the customers. They are also called Pre-Engineered Metal Buildings (PEMB) in some industry sectors. These metal buildings are different from conventional buildings in ways like speed in delivery and erection, flexibility in expansion and withstand severe weather conditions. We are a one-stop solution provider for all your structural needs and have products ranging from Porta cabins, Canopies, Mezzanine Floors, Stairs, etc. Having an experience of over two decades in this industry. We truly comply with all the ISI specifications while designing and manufacturing all our structures which ensure all-out safety and are quite economical as well, as we incorporate quality raw materials and sheets in their making.

Over the last few decades pre-engineered steel and metal buildings have become quite popular in the construction industry due to its flexibility, durability, and adaptability over. These factors have made steel one of the most sought after materials for building construction.

Our customer has a large choice for sheet material which can suit their budget as well as requirements such as pre-coated sheets, Sandwich Panel GI sheets, Fiber sheets, and Polycarbonate Sheets. In the pre-engineered building systems, one has the flexibility to accomplish an indefinite array of building configurations, custom designs, requirements, and applications. Factory sheds, warehouses, greenhouses, community halls and canopy, etc., are some of the ways where the PEB systems can be applied.

Industrial Construction

INDUSTRIAL CONSTRUCTION

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

BUILD FAST AND BUILD SMART

industrial construction

The ABR has delivered some of the most sophisticated construction and warehousing facilities in India for clients including Times of India, Dishman Carbogen Amics Limited, Eveready Industries Ltd., Frigoglass, Reliance Industries Ltd etc. Our teams have helped redefine logistics and streamline production for manufacturers across the country.

From the front office to the production line to the loading docks, we deliver end-to-end new construction, renovation and expansion services for clients—on-budget, on-time, every time.

Supporting your process, streamlining your workflow, maximizing your capacity

our industrial facility should support your operations, helping direct the flow of materials and machinery while maximizing your productive space. At The ABR, our process starts with a keen set of ears and dedicated listening to best understand just how you want to use your facility. We then design and build your facility specifically to support your operation.

From production and manufacturing to logistics and distribution, we’re seasoned in building facilities that support a range of systems and processes, including:

- Full-scale manufacturing lines

- Heavy machinery

- Raw materials processing

- Robotic KIVA systems

- Automated Storage and Retrieval Systems (AS/RS)

- Floor, wall and roof-supported conveyor systems with pick pods

When it comes to building systems and structures, we select what’s best for the job. In addition to classic brick and mortar buildings, we’ve delivered some of the most complex industrial construction facilities using a range of materials, technologies and project approaches. At the end of the day, our facilities need to perform so our clients can do what they do best.

Our team-oriented, Design-Build approach separates our industrial construction services from the rest of the construction industry. We bring collaboration and innovation into industrial construction by uniting engineering, architecture, construction and trade contracting professionals on one team from start to finish. Elements of construction can be nested and overlap with elements of design, leading to fast-track delivery and savings. Designs incorporate cost, schedule and constructability expertise, paving the way for facilities to meet the specific demands of industrial use. Our project teams identify efficiencies, savings and solutions to potential problems at project onset.

Commercial Construction

INDUSTRIAL CONSTRUCTION

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

BUILD FAST AND BUILD SMART

industrial construction

Shopping malls, supermarkets, warehouses and plants all have one thing in common: To meet investors’ and developers’ requirements, design teams have to design the building in a way that allows contractors to apply fast and efficient construction techniques in order to ensure the project’s profitability. Commercial and industrial buildings must also withstand heavy usage and workloads to maintain the continuity of business operations. With ABR, you can trust our cement, aggregate, and concrete solutions to boost your jobsites and guarantee the durability of your building while giving it an aesthetic touch.

Your challenge

When developing, designing, or contracting an commercial building, a number of key factors play a crucial role in the business success of your construction project:

- Rent or sell the building as soon as possible to maximize the profitability of your project

- Reduce repairs and maintenance so the commercial activities can run at full capacity and contribute to your business success

- For shopping malls and supermarkets, you want to attract as many customers as possible, with the help of aesthetic and appealing designs

- For specific constructions, you need high-performance resilience and thermal insulation.

Our offer

- We ensure the resistance of your industrial and commercial slab floors. Our high mechanical strength concrete supports the heaviest loads and machinery. And thanks to its high mechanical performance, the use of steel fibers is not always required, saving time at your worksite.

- We optimize the thermal performance of your buildings and data centers.

- We make your job sites quicker and more efficient. Our building efficient systems allow the concrete to be poured horizontally and the walls then mounted on-site, for faster assembly and building time.

- We have advanced fast-setting concretes that reach the maximum strength faster than traditional ones. And a portfolio of precast concrete solutions provides you with an easy assembly on-site.

- We can provide you with thermal efficient concretes, high thermal performance concrete block solutions and a range of efficient building systems that combine cement, aggregates, and concrete with insulating components to create energy-efficient construction elements such as walls, floors, and roofs.

- We add an aesthetic exterior and interior touch to your commercial buildings. Our decorative concretes and aggregates offer a variety of colors, textures, and patterns for interior and exterior fittings.

Residential Construction

HOUSING PROJECTS

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

Steps in Construction of Multi Storey Buildings

Multi Storey Buildings

Design of building component

Staircase design

Deep Beams

Slabs

Excavation, Layout and Foundation

- Excavation is a process of making trenches by digging up of earth for the construction of foundations and basements.

- Excavation is done by the JCB on the hourly basis

- After the excavation the surface is leveled called surface dressing

- Layout is done on the PCC poured over leveled surface.

- Column and foundation (raft ) steel is then laid as per drawings.

Points to be taken care of:

- Layout should be checked properly.

- Check any difference between architectural and structural drawings regarding location of column.

- After excavation check the stability of temporary structures built near the excavated ground.

- Before laying raft reinforcement, shuttering wall which is mainly brick wall should be built and should be filled with soil on other side.

- Check the direction of chair bars in the raft

Column Casting

- On the raft the column layout is done.

- Layout for starter.

- The column ties and link bars are provided as per column reinforcement drawings and general specifications.

- Displacement of main bars should be provided with L bar

- The plumb of formwork should be checked.

- Height of cast should be calculated accurately.

- Avoid caps as far as possible.

Slab, Beam, Shuttering and Casting

- Beam bottom is first laid on the column and then slab formwork is laid.

- After the reinforcement, the slab is checked for steel as per drawings and level required.

- A camber of 5 mm in provided in the center of slab.

- Casting of slab should be discontinue at l/3 from the support.

Important Components in Building Construction

- Key in Columns

- Expansion joint

- Water bar

- Binding materials

Key in Columns

- Since the height of column is very large, hence it is not possible to cast the column at one time, to cast the column later the key is made at the junction so that the proper bond between the old concrete and new concrete is formed.

- The key is only a small depression left on the concrete surface

Interior

Fire Fighting

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

Fire Fighting

We provide our clients reliable and cost-effective Turnkey Interior Designing Solutions as per their diversified needs. Our interior turnkey solutions are ideal for commercial and industrial establishments, which include factories, officesetc. Right from visualization to detailed designing, we ensure to maintain the highest standards.