ABR INFRASOLUTIONS PRIVATE LIMITED

- +91 93 1401 2773

- hamidkhan@abrinfra.com

- FF-307 'D‘, Sushant Shopping Arcade, Shushant Marg, Gurugram (HR)

- HOME

- COMPANY

- PROJECTS

- Baxter Pharmaceuticals India Privet Limited

- M/s Becton Dikinson India (P) Ltd. Bawal

- Bennett Colman & co. Ltd, Noida

- M/s BENNETT UNIVERSITY

- Caparo Fasteners

- Dishman Carbogen Amics Limited

- Eltek SGS Mechanics Pvt. Ltd.

- Eveready Industries Ltd. Lucknow

- Frigoglass India Pvt. Ltd.

- K W Group

- M/s Reliance Industries Ltd. Warehouse

- Times Internet Limited, Gurgaon

- M/s Times of India Lucknow

- Times Of India, Ahmadabad

- M/s. Reynders Label Printing India Pvt. Ltd.

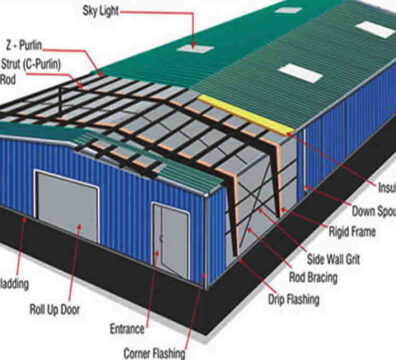

- TURNKEY SERVICES

- CAREER

- CONTACT

Book Your Meeting

HOUSING PROJECTS

Providing integrated turnkey services and out-of-the-box solutions, an edge over competitors.

Steps in Construction of Multi Storey Buildings

Multi Storey Buildings

Design of building component

Formwork design

Staircase design

Deep Beams

Slabs

Staircase design

Deep Beams

Slabs

Excavation, Layout and Foundation

- Excavation is a process of making trenches by digging up of earth for the construction of foundations and basements.

- Excavation is done by the JCB on the hourly basis

- After the excavation the surface is leveled called surface dressing

- Layout is done on the PCC poured over leveled surface.

- Column and foundation (raft ) steel is then laid as per drawings.

Points to be taken care of:

- Layout should be checked properly.

- Check any difference between architectural and structural drawings regarding location of column.

- After excavation check the stability of temporary structures built near the excavated ground.

- Before laying raft reinforcement, shuttering wall which is mainly brick wall should be built and should be filled with soil on other side.

- Check the direction of chair bars in the raft

Column Casting

- On the raft the column layout is done.

- Layout for starter.

- The column ties and link bars are provided as per column reinforcement drawings and general specifications.

- Displacement of main bars should be provided with L bar

- The plumb of formwork should be checked.

- Height of cast should be calculated accurately.

- Avoid caps as far as possible.

Slab, Beam, Shuttering and Casting

- Beam bottom is first laid on the column and then slab formwork is laid.

- After the reinforcement, the slab is checked for steel as per drawings and level required.

- A camber of 5 mm in provided in the center of slab.

- Casting of slab should be discontinue at l/3 from the support.

Important Components in Building Construction

- Key in Columns

- Expansion joint

- Water bar

- Binding materials

Key in Columns

- Since the height of column is very large, hence it is not possible to cast the column at one time, to cast the column later the key is made at the junction so that the proper bond between the old concrete and new concrete is formed.

- The key is only a small depression left on the concrete surface